- News class

- Contact us

-

Person:

Person:

Tel:+86-0769-82360478

Fax:+86-0769-82360478

E-mail:lxmoju@163.com

Address:Dongguan City Qiaotou Town Wo Wo Village Road No. 3

-

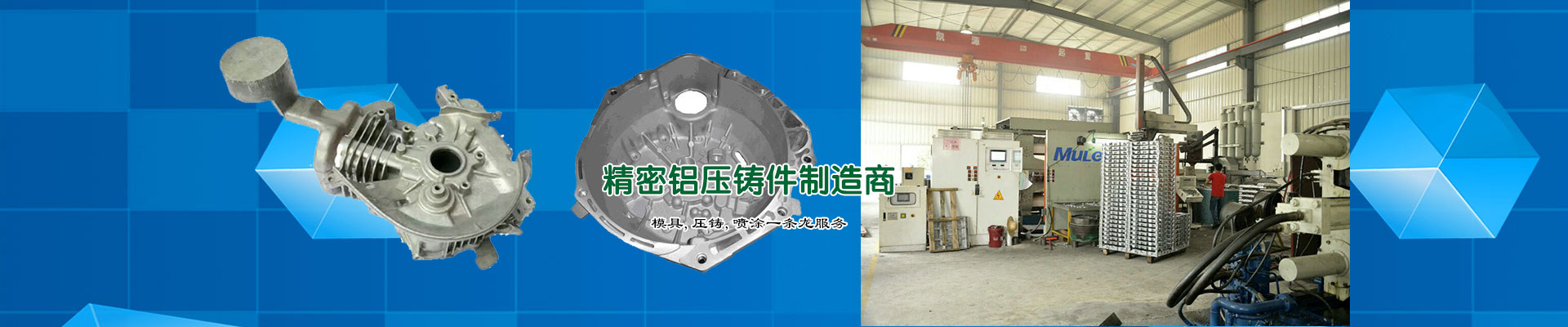

What are the characteristics of aluminum alloy die-casting parts in the production process?

Release time:2016/4/29 21:47:03 | Source of information:Jiaming precisionNow let's talk about the characteristics of aluminum alloy die-casting parts in the production process?

Pressure casting, referred to as die casting, is a molten alloy liquid into the pressure chamber, with high speed filling of steel mold cavity, and the alloy liquid in the pressure of solidification and casting method. The main characteristic of die casting is different from other casting methods, which is high pressure and high speed.

(1) the metal liquid is filled in the cavity under pressure, and in the higher pressure crystallization solidification, the common pressure is 15 - 100MPa.

(2) the liquid metal to the high speed filling cavity, usually in 10 - 50 meters / sec, and some can be more than 80 meters / seconds, through the gate into the cavity of the line speed - ingate speed), so the liquid metal filling time is very short, about 0.01 - 0.2 seconds (must be apparent casting size and different) can fill the cavity. Die casting machine, die casting alloy and die casting die are the three main factors of die casting production.

So-called die casting technology is to these three elements organically integrated use, enable stably with rhythm and efficient production of appearance and inner quality good, the size to conform to the pattern or agreement to the requirements of the qualified casting, even the high quality castings. The fluidity of die casting is the ability of the alloy liquid to fill the mold. The size of the liquid determines whether the alloy can be cast complex. In the aluminum alloy, the fluidity of the eutectic alloy is the best.

There are many factors affecting liquidity, mainly is the composition, temperature and alloy liquid in the presence of the solid particles from metal oxides, metal compounds and other pollutants, but outside of the fundamental factors for the level of pouring temperature and pouring pressure (commonly known as pouring pressure head). In the actual production, in the alloy has been determined, in addition to strengthening smelting process (refining and deslagging), it is also necessary to improve the casting process (sand mold permeability, metal mold venting and temperature) and the pouring temperature is improved without influencing the quality of castings under the premise to ensure the mobility of the aluminum alloy.In the previous:At present, the different defects of die castings have been a difficult point in the process of die casting.The next article:In the production process, aluminum alloy die casting defects have?