- 新聞分類(lèi)

- 聯(lián)系我們

-

手機(jī): 13712986357 電話: 0769-82360478 傳真: 0769-82360478 郵箱: lxmoju@163.com 地址: 東莞市橋頭鎮(zhèn)禾坑村禾石路3號(hào)

-

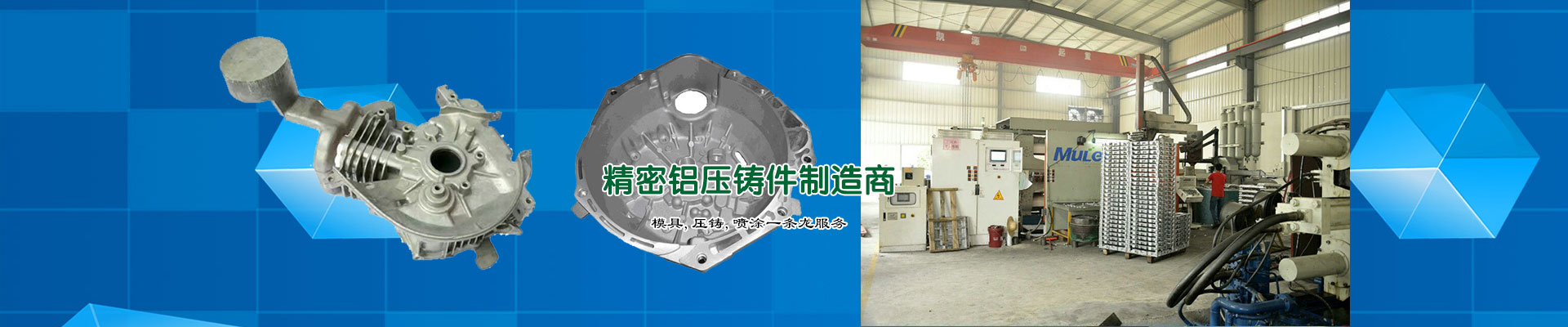

Soldering and melting loss phenomenon Aluminum Alloy mold and its measures

發(fā)布時(shí)間:2016/4/29 21:39:36 | 信息來(lái)源:Jiaming precisionTo efficient production of alloy die castings, reduce the maintenance time of the die to be, the development and introduction of new thermal mold material, and the optimization of heat treatment on the structure and properties of the mould material, we come to common concern by surface treatment to prolong the service life of the mold of the topic. In this paper, we discuss the soldering and melting loss phenomenon Aluminum Alloy pressure casting and its preventive measures

Die casting process, the filling time of the cavity is generally 0.1s, or even less, the speed of the alloy through the gate is about s 40~60m/, and some even up to s 200m/. The compressive strength of metal during solidification is usually around 40 ~120MPa. In the aluminum alloy die casting, die casting die working surface temperature generally can rise to 500~600. For the manufacture of a small aluminum alloy parts, the entire die-casting - solidification cycle time of about 3~6s, large aluminum alloy parts are not more than 90s.

In each cycle of the early die casting, mold cavity to withstand hot molten alloy quenching effect, the surface will produce heat of compression stress; after the end of the die casting in the mold spray lubricant, rapid cooling, and on its surface to produce tensile stress. Under the action of alternating thermal stress, thermal fatigue crack will be produced on the surface of the die, and the micro crack will expand rapidly with the increase of the number of die casting cycle. If the cracks around the same time with the molten alloy on the mold cavity of the erosion and corrosion, the mold surface will be further damaged, resulting in the early cracking of the mold and even scrapped.

1 Aluminum Alloy welding phenomenon in die casting mould

In all the major causes of Aluminum Alloy die failure, welding die surface generation problem gradually began to get attention. "Bonding" is in the die casting industry terminology, it refers to the reaction between the mould and die casting alloy. The mold surface in the event of a welding, it will generate complex Fe Al intermetallic compound phase, and in the next die casting cycle on the surface of the casting defects caused by. Hard metal inter phase but also in the mold surface accumulation. Therefore, it is necessary to interrupt the production and polishing method is used to remove the welding product, it will lead to prolong production time and labor waste, but also reduce the service life of the die.

Usually according to welding in different forms, can be divided into two kinds of "welding".

The first form is called "the impact of welding welding, welding is occurred on the surface of the mould in casting or toward the entrance of the cavity. These regions in filling are generally subject to violent impact of molten metal flow, surface temperature is higher, under pressure from larger, the protective layer is easily damaged, in continuous scouring alloy die-casting mold protection layer failure and to expose base metal, alloy and substrate material occurred reaction produces a complex intermetallic compound phase. Intermetallic compound is hard and difficult to deformation, shedding its rupture in the die-casting will not only lead to the quality defects of castings, and will take the matrix material, and the freshly exposed surface, so the cycle, the soldering phenomenon gradually deepened, serious when will lead to mold surface by corrosion and mould material melting loss. Therefore, must be timely removal and repair the damaged surface in early welding.

Second kinds of welding form called "welding deposition", namely the welding position back to far from the gate or gate. These areas are usually the places where surface treatment or die lubricant can not be achieved. Therefore, their surface state, temperature distribution, pressure and other places are different. Usually die casting alloy after reaching these areas in low temperature, its liquidity is poor, easy first solidification, hot semi solid alloy and die surface contact time longer, here on a mold surface state and is not very ideal, it is easy to form FeAl intermetallic compounds, in the repeated cycle of die casting, the intermetallic compound will be in areas of poor liquidity in these sediments gradually, and finally the formation of serious welding and die casting production.

Although in aluminum alloy die casting die different areas of different forms of welding, but the welding has some universal common feature - the mold surface welding area shows a silvery sheen.

Welding layer composition, often complex Fe Al intermetallic compounds, and due to the composition of the layer of intermetallic compounds is thin, so in the analysis also some difficulties. But foreign researchers Z.W.Chen and D.T.Fraser etc. using X-ray diffraction analysis of intermetallic compounds in the melting Al-11Si-3Cu die casting aluminum alloy dip dip H13 steel generated metal structure, they think, welding layer by the complexes between metal layer compound alpha a BCC FeSiAlCrMnCu, outer layer of compact layer of hexagonal H-alpha Fe2SiAl8 intermetallic compounds and the inner compact layer orthorhombic ETA -Fe2Al5 metal compound composition. And they filmed the Fe-Al interface organization and the author's "in ADC12 die casting aluminum alloy dipped in H13 steel" test is very similar to the Fe-Al interface.

Intermetallic compound very little amount of bonding surface layer and thin and analysis means, in the current stage, researchers at home and abroad are only the general qualitative analysis. As for the formation and development of law of welding layer, quantitative analysis will be of intermetallic compounds is the research focus in future work.

The melting loss effect 2 Aluminum Alloy mold

By hot melt, semi solid alloy erosion and maintain compression state of aluminum alloy die casting die in use after a period of time, the surface protective layer generally the formation of reticular micro crack, crack or even surface layer off. If the mold surface repair and maintenance, it will be more serious, the so-called "melting loss" effect. "Melting loss" refers to the mold in the work for some time, the working surface is seriously eroded, so that the quality of the mold has become light too.