-

In the production process, aluminum alloy die casting defects have?

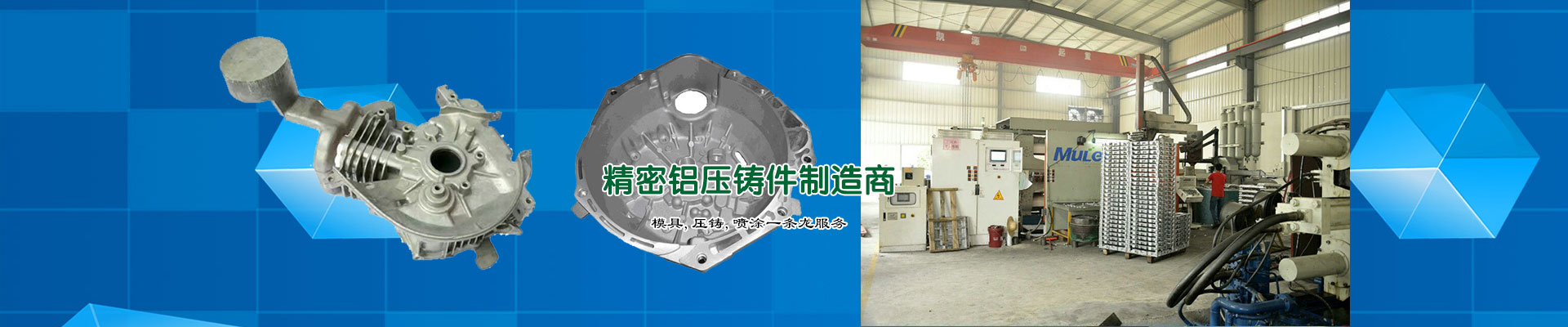

發(fā)布時間:2016/4/29 21:45:44 | 信息來源:Jiaming precisionLet's talk about in the production process, which has the defects of Aluminum Alloy casting?

The defects in Aluminum Alloy Aluminum Alloy die casting production process of our common casting for the five main defects referred to as cold. Crack. Shrink. Off gas.

Cold: refers to the casting surface rough uneven. Cold water with lines.

Crack: refers to the sticking crack. Top crack. Cold cracking. Low mold temperature shrinkage crack.

Shrinkage: refers to the casting surface uneven depression.

Gas: refers to the feed at a casting hole. The overflow slag mouth has pores. The casting surface bubbles. Casting internal pores.

Removal: refers to the casting surface with a thin layer of like a thin layer of the same as the one we call him peeling. There is a thick thin surface is very small and there is little more. Some side of the thin side from the other side and casting into the body we call him separated from the skin.

According to different production conditions, die-casting parts in the production process will appear different problems, but the five pressure casting defects are the most frequently occurred, then we have to do?

A: to understand die casting production process and find out the correct feeding range.

Two: know the weight of the product. The sprue need to locate.

Three: understand the product structure. How to use the runner. The runner is the guide channel.

Four: understand the product structure. To open the inner gate. A Piao. Two import. Multichannel import.Pearl imports, as long as you unzip cast from these aspects can solve five major defects.

全國服務熱線

13712986357