- News class

- Contact us

-

Person:

Person:

Tel:+86-0769-82360478

Fax:+86-0769-82360478

E-mail:lxmoju@163.com

Address:Dongguan City Qiaotou Town Wo Wo Village Road No. 3

-

What are the main features of stamping parts processing?

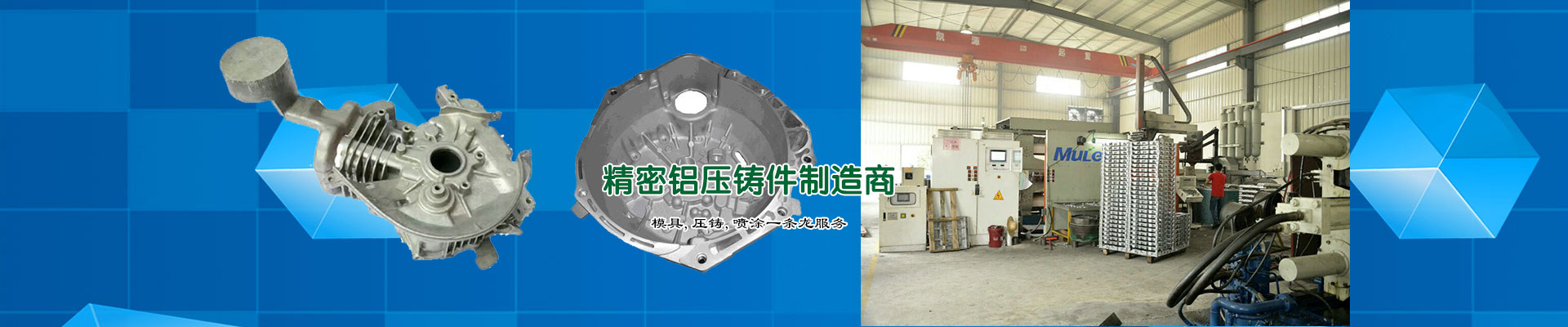

Release time:2016/4/29 21:57:49 | Source of information:Jiaming precisionStamping is the installation in the press mold, to placed in die in sheet metal deforming force, so that the sheet metal in the mold deformation, to obtain a certain shape, size and performance parts of the production technology. The stamping process often carried out at room temperature, so it is also called cold stamping.

Stamping is one of the metal pressure processing method, it is established in the metal plastic deformation theory based on the material forming engineering technology, stamping processing raw materials general board material or strip, and therefore it is also called sheet metal stamping. The stamping process is a specific method of stamping (the sum of all kinds of stamping process) and technical experience; stamping die refers to sheet metal stamping parts into special tools

Stamping processing is mainly metal or non metal sheet, with the pressing pressure, by stamping die stamping forming. It has the following characteristics:

1) stamping is under the premise of material consumption is little, the manufacture of stamping out, whose parts are light weight, rigidity good and sheet metal after plastic deformation, the inside of the metal structure was improved, the punching strength can be improved.

2) stamping parts with high dimensional accuracy, the same module size is uniform and has good interchangeability. Does not need further machining can meet the general requirements of assembly and use.

Weapons, household electrical appliances and light industry and other industries are stamping and processing for the 3) stamping in the stamping process, due to the surface of the material is not damaged, so it is a better surface quality, appearance is smooth and beautiful, the surface paint, electroplating, phosphating and other surface processing provides a convenient conditions. Not only is the industry widely used it, and every person every day and directly related to the production of stamping products. Stamping can be used in the production of watches and clocks and instruments in the small precision parts, but also can make cars, tractors, large covering parts. Ferrous metals, non-ferrous metals, and certain non metallic materials can be used in the stampingIn the previous:Die casting aluminum alloy plating surface treatment solution?The next article:What is the scope of application of metal stamping parts?