- News class

- Contact us

-

Person:

Person:

Tel:+86-0769-82360478

Fax:+86-0769-82360478

E-mail:lxmoju@163.com

Address:Dongguan City Qiaotou Town Wo Wo Village Road No. 3

-

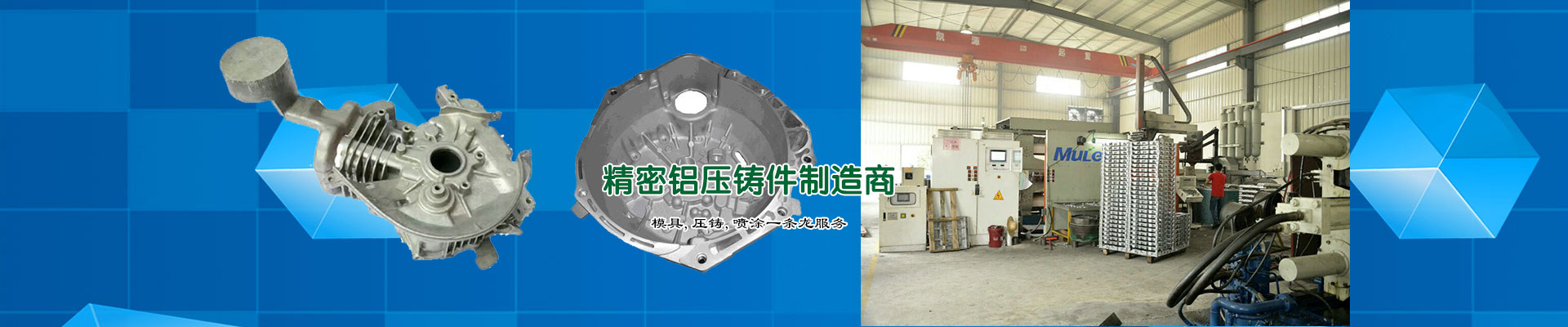

Die casting aluminum alloy plating surface treatment solution?

Release time:2016/4/29 21:59:12 | Source of information:Jiaming precisionDie casting aluminum alloy containing Si for 6.5% ~ 7.5%, high Si content to make the material in the die casting process has good fluidity. Die casting aluminum, light weight, good mechanical strength, electrical conductivity, good thermal conductivity, no magnetism, and can be used in die casting technology of high precision casting of complex parts. But the die casting aluminum alloy electrodeposits poor adhesion, corrosion resistance performance needs to be improved, from the functional cost and can consider plating color zinc and chromate treatment.

. die casting aluminum alloy surface plating color zinc aluminum itself is an amphoteric metal, in acid or alkaline solution is not stable, coupled with loose organization of die casting aluminum alloy itself, trachoma, pores and other defects, often affect the plating quality.

After proper pretreatment, die casting zinc plating becomes easy, zinc plating around 10um layer and passivation treatment can exponentially increase of die-casting aluminum alloy corrosion resistance, in order to prevent discoloration of color zinc can be dip coated with a layer of organic protective film.

Two. Die casting Aluminum Alloy surface chromate treatment. Die casting aluminum alloy after sandblasting processing can be directly chromate treatment and the surface can obtain a layer of passivation film, according to the needs of this layer of film can be colorless to yellow, and does not affect the surface resistance, in order to achieve the requirements of protection can be in chromate treatment, spray.In the previous:壓鑄件壁厚對(duì)鑄件質(zhì)量起至關(guān)重要的作用The next article:What are the main features of stamping parts processing?